ALICE photo-injector ceramic vacuum joint collaboration

You can download a more detailed powerpoint version of the material in this web page.

History

Daresbury Laboratory has pioneered the use of 'bulk resistive' ceramic for the high voltage insulator used to isolate the ALICE Cathode assembly, which must be brought to around -400kV DC potential.

The bulk resistive properties give the ceramic a resistive effect equivalent to around 60 G?, which divides the applied DC voltage across its length, and protects the ceramic against bombardment of electrons from any field emitters on the Cathode assembly.

The bulk resistive ceramic proved itself to be a great success electrically. Its voltage division properties are ideal for the application. Based upon Daresbury's experience, both Cornell University and Jefferson Laboratories FEL projects in the USA have ordered identical bare ceramics to DL's design from the UK manufacturer Morgan Crucibles American subsidiary WESGO in the USA.

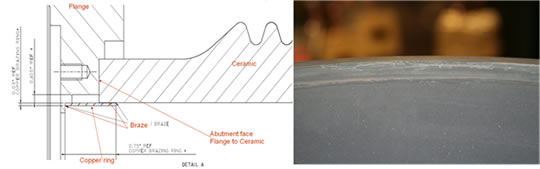

The major issue with the ceramic has been with the ceramic to metal joints at each end, where the flange is attached. The sheer size of this ceramic has resulted in difficulties in obtaining a durable vacuum joint, capable of being repeatedly baked to 230 C, which is essential if pressures as low as 3 x 10-11 mB are to be achieved within the injector. The original internal copper ring jointing technique applied was developed by Cornell University and CPI, a commercial klystron manufacturer.

This joint failed on all three of DL's ceramics. As part of the failure investigation, the copper joint ring and metallisation were removed. The findings were that the stresses during bakout at the ceramic/metallisation boundary were so great that the ceramic was being literally torn off. A better solution was urgently required.

Meanwhile, a smaller diameter ceramic insulator borrowed from Stanford University was installed on the ALICE gun which limited the maximum gun voltage to 230 kV compared to the orginally planned 350 kV. The ALICE gun ran at this voltage from 2008 to 2011.

Ceramic Development

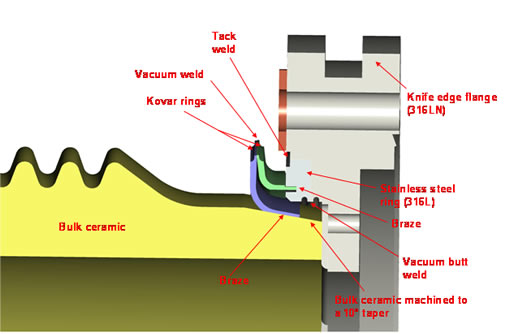

With Daresbury, JLAB and Cornell requiring a viable solution to the sealing problem, a collaboration between the laboratories and CPI was set up in order to pool knowledge and experience and produce a reliable design. It was decided to progress two techniques. A modified external kovar tapered braze joint and a monel butt joint, which are shown in the diagrams below.

Daresbury Designed External Kovar tapered braze joint and detail of attachment to the 14” Flange

Collaboration Designed Butt braze joint showing detail of attachment to the 14” Flange (displayed above) Latest Developments

In 2012 the cermaic design with monel butt braze joint was installed on the ALICE DC gun, enabling gun voltages of up to 400 kV to be reached. Currently in 2012 the ALICE gun operates at 325 kV.