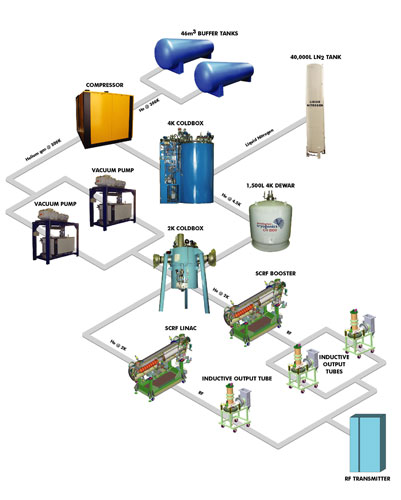

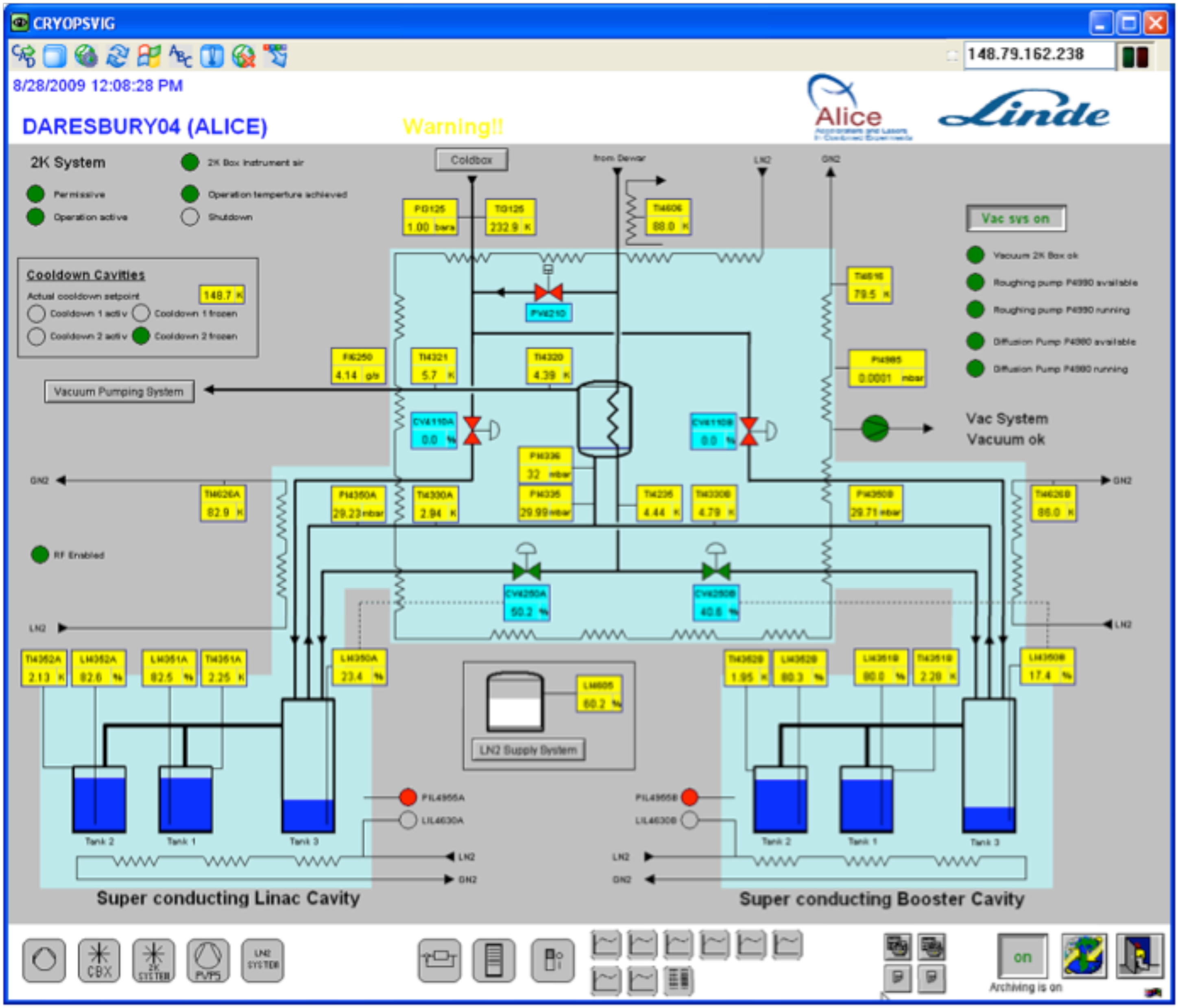

The ALICE cryogenics system cools and maintains the two superconducting RF modules at an operating temperature of 2 Kelvin. The system design is based on the combination of concepts from the ELBE and HoBiCaT cryogenic systems and has the capacity to operate with a dynamic (RF induced) heat load of 118W at 2K. The system consists of a Helium compression system, 4K liquefier, liquid Helium storage Dewar, 2K Coldbox containing a 2K counter flow heat exchanger and 2 ambient temperature Vacuum pumping systems. A system diagram is shown below.

The system operates by using the 4K Coldbox to produce an inventory of liquid Helium which is held within the Liquid storage Dewar. The cavities are then cooled using a tightly controlled mix of warm and 'cold' gas from different sources within the 4K Coldbox to produce a cool down rate of 30K/h between 300K and 150K. At temperatures between 150K and 90K the cooldown rate must be increased to 180K/h, this high cooldown rate ensures that the RF cavities do not lose efficiency as a result of Q disease affecting the Niobium. On ALICE this is achieved by injecting liquid directly into the cavities, ensuring as fast a cooldown rate as possible is delivered, During this part of the "cooldown" the liquid feed valves are opened once the cavity temperature reach 175K. Below 90K cooldown rates are unlimited.

Once the cavities are filled with liquid, the helium gas space above is pumped by the Vacuum pumping systems. The Vacuum pumps reduce the vapour pressure in the cavities from approximately 1100mbar to the 30mbar required for operation at 2K. The cold return gas from the cavities is heated by a 15kW heater prior to reaching the vacuum pumps.

The pressure in the cavities must be closely controlled to maintain them at the required frequency of 1.3GHz, the pressure is controlled at the first common point on the return pipes from the cavities. The design parameters of the system specified pressure stability control to be within ±0.1mbar, operation has proven pressure stability of ±0.03mbar.

Even though standard 2K operation is at 30mbar, tests have been performed on the system to prove its operation at 1.8K. 1.8K (16mbar) operation has been achieved with a dynamic heat load of 50W.